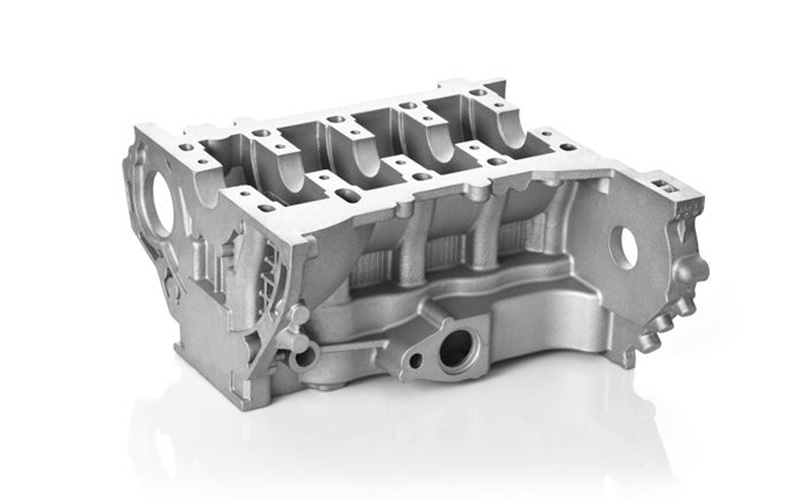

The cylinder block in diesel engine is the skeleton of the whole engine. All the peripheral parts of the engine are directly installed on it, such as crankshaft, cylinder head, fuel injection pump, flywheel, etc. The quality of the cylinder block itself is crucial to the quality of the entire engine. Due to the requirements of the diesel engine, the cylinder block is generally made of cast iron to provide the strength and vibration resistance required by the whole engine.

The influence of coarse datum on cylinder block

The casting is prone to deformation during pouring. When selecting the machining location, it is necessary to reasonably select the registration point according to the specific casting situation, reasonably allocate the deformation amount of the cylinder block caused by casting, and reduce the influence of deformation to an acceptable range. In the machining process of the cylinder block, the center of the screw hole of the cylinder block and the casting partner of the blank do not coincide, the machining allowance of each cylinder hole is not uniform, and the quality problems such as thin wall appear in the key parts, which is often related to the improper selection of the standard for rough machining of the cylinder block.

Typical coarse benchmark selection

Taking the selection of the primary rough machining datum of the cylinder block of a six-cylinder in-line engine as an example, this paper illustrates how to select the positioning datum of the first process of the cylinder block. As shown in figure 1, the cylinder block is a wet cylinder liner, HT250 material, and the blank is a casting.

Due to the first sequence processing, it is necessary to process the process positioning reference for the subsequent processing process, so it is necessary to complete the positioning of the cylinder block. The selection of positioning datum for the first sequence machining of the cylinder block is shown in FIG. 2 (bolded line). The center of the upper cylinder hole of the blank cylinder block, the inner side of the semicircular hole of the seventh crankshaft and the center of the middle gear are selected respectively.

The following is the analysis of the limitations of positioning on the freedom of the cylinder block. For the sake of illustration, the cylinder block is placed in the coordinate system

The center limit of one cylinder upper bore, the inner limit of one and seven crankshaft semicircular bore, the center limit of the middle gear, the 6 degrees of freedom of the cylinder block are completely limited, so the positioning is a complete positioning.

The fixture for the first sequence processing of the cylinder block is located at the inner side of the semicircular hole of the seventh crankshaft, at the center of the middle gear of the cylinder block at the second position, and at the center of the upper cylinder hole of the cylinder block at the third position. The parts are in the clamping state.

The selection of general coarse datum needs to consider two aspects: one is to ensure the mutual position accuracy requirements between the machined surface (hole) and the non-machined surface (hole); Second, reasonable distribution of the machining surface (hole) machining allowance.

Are these two requirements taken into account in the selection of coarse datum for the cylinder block? First of all, we need to know the casting condition of the cylinder block. The main casting sand core of the cylinder block is divided into main body core, upper cover core, lower cover core, front end insert core, back end insert core and water sleeve core.

During casting, the upper and lower cylinder holes of the cylinder block are formed at the position of sand core 1 in FIG. 5, the two sides of the main bearing seat of the cylinder block are formed at position 2, and the inner side of the semicircular holes of the seven crankshafts are formed at position 3. That is to say, the cylinder block coarse datum selection are the main body core formed by the surface and hole. When casting the core, the core is formed on the basis of the main core, and the position of other sand cores is relative to the main core. The stability of the main core directly determines the stability of other cores. Therefore, it is undoubtedly correct to choose the stable surface and hole of casting.

In the actual pouring process, the casting will inevitably be deformed. According to the analysis of the shape of the cylinder block, the direction of deformation is in the direction of the length of the cylinder block, and the deformation of the length direction affects each cylinder hole and two end faces. If the processing allowance of each cylinder hole cannot be reasonably allocated, it may lead to quality problems such as the subsequent cylinder hole can not be processed, the water gap is small, and the end face can not be processed, which will directly lead to the scrapping of parts. In this case, the coarse datum is positioned in the length direction, and the center of the middle gear of the cylinder block is selected, which is equivalent to distributing the deformation amount from the middle of the cylinder block to both ends, so that the influence of deformation can be reduced to Less

For the orientation of the left and right sides, the cylinder hole center of the cylinder block is selected, and the machining allowance and casting deformation of the left and right sides are distributed to both sides based on the cylinder hole center of the cylinder block. The choice of the center of the upper cylinder hole is to reduce the rotation Angle error to as small as possible.

Conclusion

From the above analysis on the selection of coarse datum, it can be seen that the selection of the positioning datum conforms to the selection principle of coarse datum, and is a good selection method, which has reference significance for the selection of similar rough machining datum of cylinder block.

Page location :

Page location :