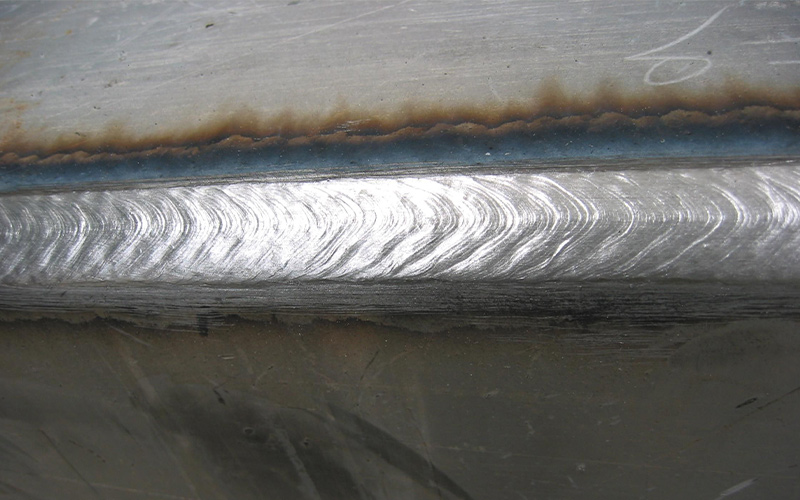

CO2 arc welding is a high efficiency welding method, with CO2 gas as the protection gas, rely on the arc between the welding wire and welding pieces to melt metal gas welding method called CO2 welding. This welding method USES welding wire automatic wire feed, apply large amount of metal, high production efficiency, quality stability. Therefore, it is widely used at home and abroad. Compared with other arc welding, it has the following characteristics:

1. High production efficiency CO2 arc welding has strong penetration, large penetration depth and high melting rate, so the deposition speed and production efficiency are 3 times higher than manual arc welding.

2. Low CO2 welding cost is only 40-50% of the cost of submerged arc welding and manual arc welding.

3. Compared with the butt weld of 3mm thick steel plate, the power consumption of low-co2 arc welding and coated electrode is 30% lower per meter than that of the butt weld of 25mm steel plate, and 60% lower than that of the butt weld of 25mm steel plate.

4, wide application range no matter what position can be welded, the thin plate can be welded to 1mm, the thickness is almost unlimited (using multi-layer welding). And the welding speed is fast and the deformation is small.

5. Strong embroidery resistance, low hydrogen content and strong crack resistance.

6. Slag cleaning is not required after welding, and arc starting operation is easy to monitor and control, which is conducive to realize mechanization and automation of welding process. Great achievements have been made in CO2 welding equipment, welding materials and welding process in China. CO2 arc welding is widely used in shipbuilding, locomotive, automobile manufacturing, petrochemical, engineering machinery and agricultural machinery in China.

Page location :

Page location :

Contacts:General manager Zheng

Contacts:General manager Zheng Tel:+86-411-6687-9288

Tel:+86-411-6687-9288 Address:No.3Buliding No.3 HuaiHe Zhong Road DDA Dalian City Liaoning Province P.R.China

Address:No.3Buliding No.3 HuaiHe Zhong Road DDA Dalian City Liaoning Province P.R.China