ISO9001Certification factory

(Integrity, win-win, development and innovation)

- Home

- About us

- Product Center

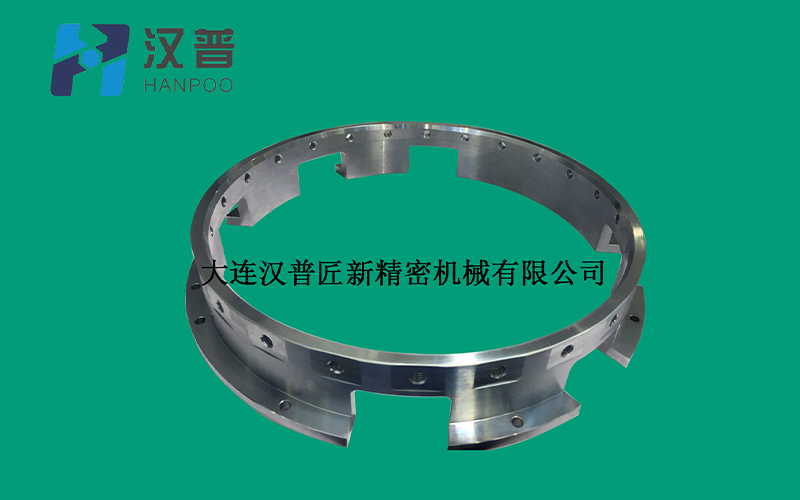

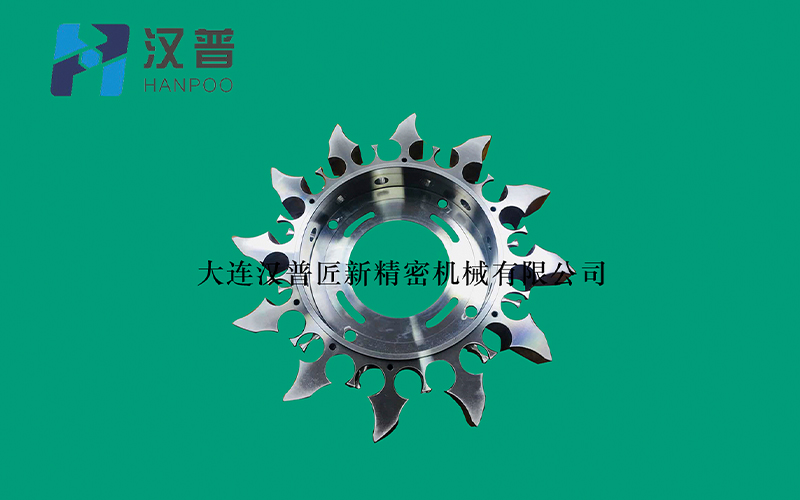

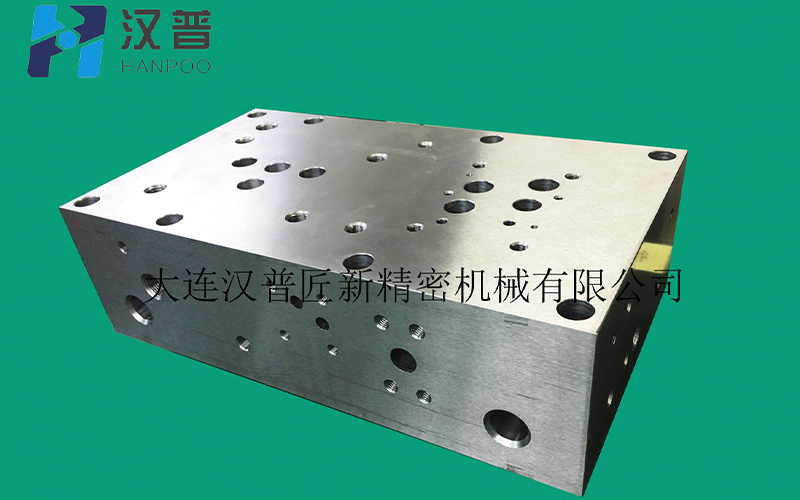

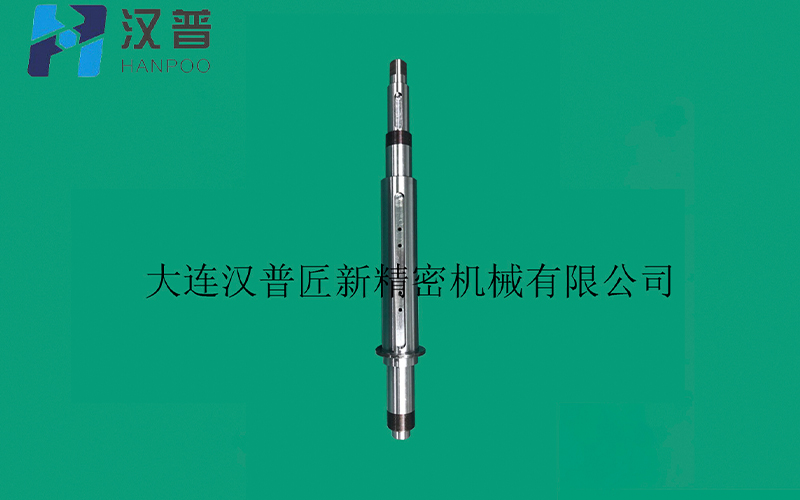

11111Handlebar Lathe parts Ultrathin parts Arc welding Welded structural part Tool changing arm Detailed specification of CO2 welding Cover sheetFluid power componentMedical equipment partsPhotovoltaic equipment partsStar tooth Hydraulic circuit block Wear resistant liner Fine spool Radiator Heat exchanger Seal plate Clamp ring Special-shaped parts MandrelUniversal machine tool partsLocomotive and ship parts

- Device display

- International trade

- News information

- Contact us

Page location :

Page location :

Contacts:General manager Zheng

Contacts:General manager Zheng Tel:+86-411-6687-9288

Tel:+86-411-6687-9288 Address:No.3Buliding No.3 HuaiHe Zhong Road DDA Dalian City Liaoning Province P.R.China

Address:No.3Buliding No.3 HuaiHe Zhong Road DDA Dalian City Liaoning Province P.R.China