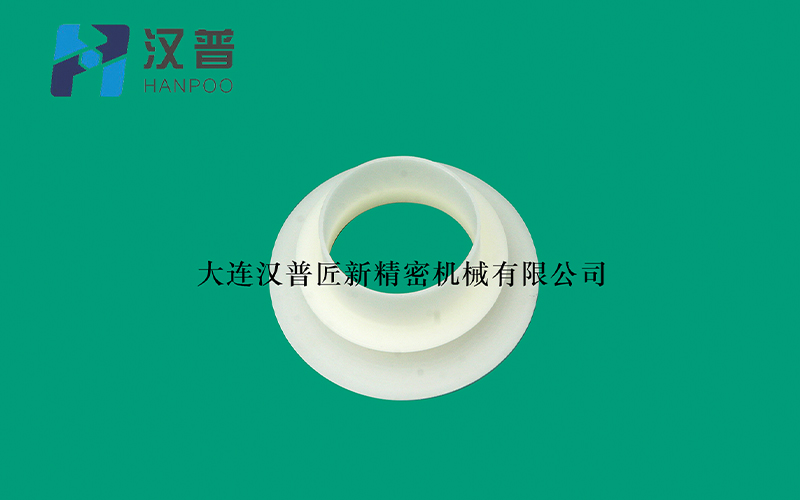

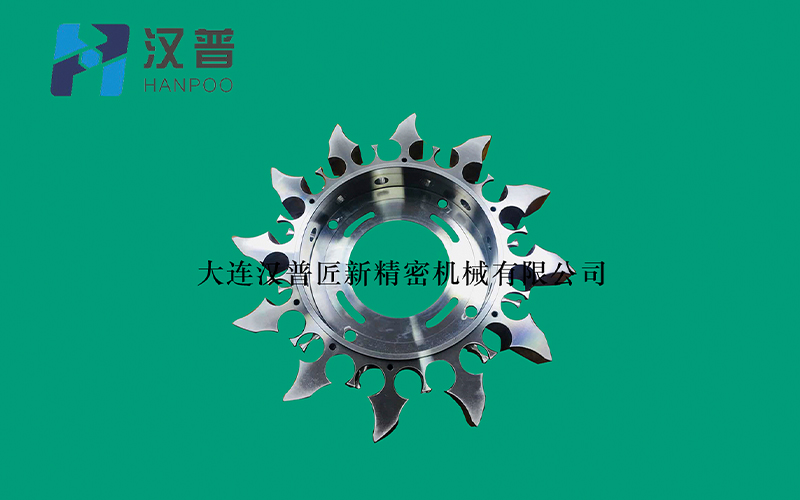

Nylon has good comprehensive performance, including mechanical properties, heat resistance, abrasion resistance, chemical resistance and self-lubrication, and low friction coefficient, have certain flame retardant, easy processing, suitable for reinforced with glass fiber and other packing, improve performance and expand the application scope, secondly the overload protection function, when the torque is too big, the gear itself damage, power transmission interruption to protect the lower device or security in life, reduce the loss.

Because nylon has non-toxic, light weight, excellent mechanical strength, wear resistance and good corrosion resistance, so it is widely used to replace copper and other metals in machinery, chemical, instrumentation, automobile and other industries to manufacture bearings, gears, pump blades and other parts. Polyamide is fused and spun into silk with high strength. It is mainly used as synthetic fiber and can be used as medical suture. It is the true meaning of self-lubricating nylon, in the process of casting formed a liquid lubrication system, so that the service life of oil nylon bearing significantly increased, up to ordinary nylon 6 bearing life 6 times and phosphor bronze bearing life 25 times! The lubricant contained in oil nylon will not be lost, absorbed, and depleted, nor will it need to be re-added. Lubricants in oil nylon greatly broaden the use of nylon, especially for some parts that cannot be lubricated.

Page location :

Page location :

Contacts:General manager Zheng

Contacts:General manager Zheng Tel:+86-411-6687-9288

Tel:+86-411-6687-9288 Address:No.3Buliding No.3 HuaiHe Zhong Road DDA Dalian City Liaoning Province P.R.China

Address:No.3Buliding No.3 HuaiHe Zhong Road DDA Dalian City Liaoning Province P.R.China