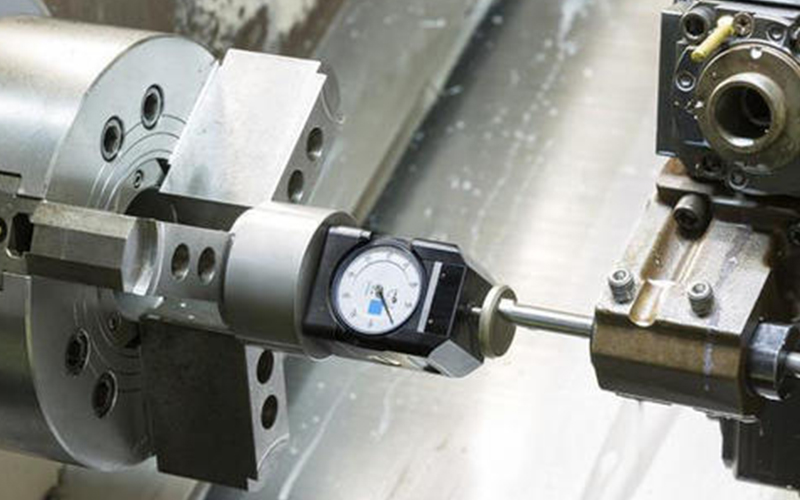

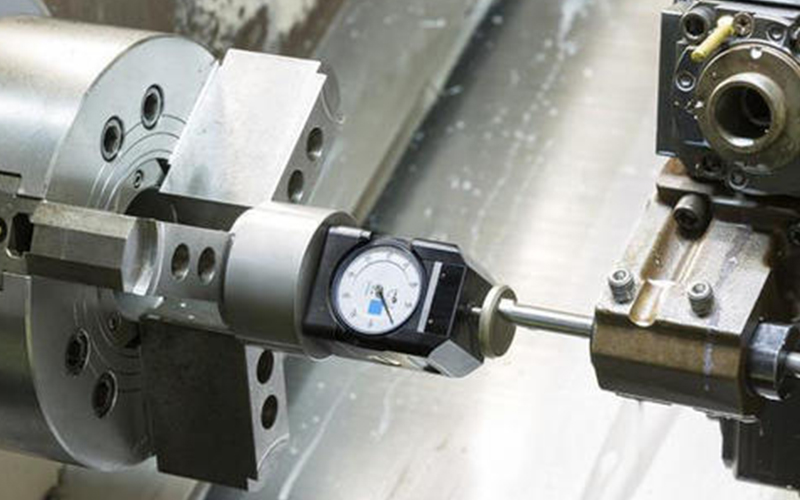

In precision machining, grinding is an important means to ensure the accuracy. Grinding is mainly divided into plane grinding and internal and external grinding. The following Dalian machining small series will take you to understand.

The shape and distribution of grinding cutting edge are irregular and random, and their shapes, sizes and positions are different. When machining precision mechanical parts, the cutting thickness is thin, generally less than 5 μ M. the power grinding is different from the slow feed grinding. The grinding energy of the former is larger than that of the latter, which is more than 10 times of milling, that is to say, the cutting energy consumption is large.

Grinding is different from general precision machining process. It is not a pure mechanical process. There is high temperature and high contact pressure between the abrasive particles and the workpiece interface. The temperature is close to the melting point of the workpiece material. The interface pressure can reach the level of plastic deformation flow at the abrasive surface.

The grinding speed is fast, which is tens to hundreds times of other cutting speed. For metal cutting, it has a higher removal rate, and the grinding temperature is also high. In order to prevent the precision mechanical parts from contacting the grinding wheel, there are special requirements for the grinding fluid during grinding.

In the machining of precision mechanical parts, the grinding process is generally considered to be three-stage, that is, sliding friction - thermal stress generated by elastic friction and deformation stage; plough - internal friction of processed materials, the surface layer of workpiece has not only thermal stress, but also deformation stress due to elastic and plastic deformation, which affects the surface roughness and surface processing quality of precision hardware workpiece, and the front edge surface of abrasive grains There is no chip flowing out from the upper part of the workpiece; cutting - the workpiece material slides along the shear surface to form chips, which produces thermal stress and deformation stress on the surface of the workpiece.

When the grinding temperature is higher than other cutting temperatures, the workpiece can be divided into three parts: the grinding point temperature -- the temperature of the contact part between the abrasive cutting edge and the chip is the grinding heat source and the highest temperature point, which affects the metallographic structure and physical and mechanical properties of the surface layer, and is related to abrasive wear and cutting fusion. Grinding zone temperature the average temperature of the contact zone between the grinding wheel and the workpiece, which is closely related to grinding burns and grinding cracks. The temperature rise of workpiece is generally small, which only affects the dimensional accuracy and geometric tolerance. About 80% of the cutting heat is transferred into the workpiece, 4-8% of the cutting heat is transferred to the grinding wheel.

Dalian Hanpu Jiangxin Precision Machinery Co., Ltd. was established in 2010 (formerly known as Hanpu machinery processing factory in Jinzhou District of Dalian). It is a comprehensive machinery processing and international trade enterprise mainly engaged in designing and manufacturing all kinds of fixtures, precision mechanical parts, machine tool parts and mold accessories. Please call us for advice.

Page location :

Page location :