A machining center has three directions of the feed axis, respectively is X, Y, Z direction, that is, we often say horizontal, vertical and vertical, the three directions of the stroke setting method is actually the same, as long as you understand one of the other several directions of the stroke setting is very simple.

The travel setting of a machining center mainly involves three main functional parts: drive screw, drive guide and protective cover (actually this item is not important, but because a lot of design errors will be more prone to appear in this place, so for equipment operation and maintenance, to focus on).

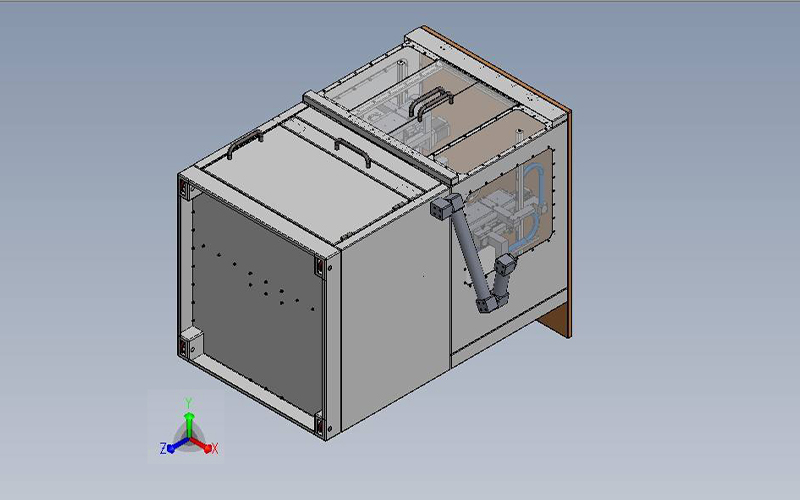

The view is a simplified version of the working table and the saddle part of a vertical machining center. I have deleted many functional parts, leaving only the driving rail and driving screw. We use this figure to illustrate how the travel of this item is set.

1. Effective travel of screw rod. Generally speaking, when we design the machining center, the travel of each direction is basically determined by the travel of screw rod.

X is equal to (A B) -40mm

For chestnuts, generally speaking, when we design the X = 800 mm (1000 mm), we try to take an integer, which is why we go to see a device, their trips are integers, rarely a direction of travel is similar to the 807 mm such Numbers, lose the 40 mm is a safe distance, usually gives the safe distance of about 20 mm, fat daring, of course, some people, also have to 10 mm, but for the safety distance is too short, when fast feed, if the motor brake failure, it is easy to cause the screw nut and screw and the collision of the bearing, This is not good for the geometric precision of the machine tool, so we usually give a safe distance of 20mm to each side, of course, if the motor brake failure, the 20mm is of no help, is a kind of design on the comfort.

So, when you do equipment operation and maintenance, if it involves redesigning the machine tool's stroke, first... To the position of the reference is screw, the screw to open to two limits, and then measure the machine can realize how much travel in the direction, then it is ok to set aside a safe distance from, if it is your company as a product of processing from the need to make a certain distance in the machine tool processing, can also take a look at the machine's screw actual running distance, in general, it must be longer than nominal schedule, as long as according to the actual distance to set up, so you can get more processing schedule, it is a very flattering way for many manufacturers, Because some parts of the processing is really only a few millimeters, as long as you know how to set the principle of travel, it can be very easy to solve their own problems.

If we talked about this trip Settings, we say through a little, we can see from the graph, and screw on the screw bearing motor seat we have installed the anti-collision rubber, rubber role is to prevent the collision screw nut and housings, motor rigid collision, have the effect of a buffer, so professional manufacturer can do these two things, but this little device has a trick, I buried a BUG in the above and see who can see out, also be to one's deceased father grind practitioners, can see the BUG must have their own independent design ability and the ability to think of the practitioners.

2. Effective travel of the guide rail. When we set the travel of the machine with the effective travel of the lead screw, we must pay full attention to the effective travel of the guide rail.

P > X 40mm crash-proof rubber width *2

X is the travel of the lead screw. Why add 40mm? Because we want to ensure that even if the workbench of the screw is beyond the safe distance, on the guide rail slider still cannot slide guide rail, or "big pearl beads machine tool", guide rail sliding block is the cycle of rolling a bead inside, if the slider from the guide rail, the rolling bead will spread out, basically can't hold back, it means that this guide rail, so the guide rail journey with this distance; Plus anti-collision rubber distance multiplied by 2 at the same time, it is because in the screw nut and screw housings, screw motor collision, collision deformation of rubber will be hit, will be compressed, this time schedule X will be further amplified, we still want to ensure the effective guide rail journey to absolute X be amplified, so guide rail trip P we usually is recommended for:

P= X 40mm crash-proof rubber width *2 40mm

It is still a safety margin of 20mm on each side. Only such a design can truly ensure that the lead screw runs to the limit, and the guide rail is still a distance guarantee that the slider will not slide out of the guide rail. Such a design is really a comprehensive design.

In fact, a lot of people do these designs, not fully considered, or even randomly set a length, is not long or short, the result is that either the travel is not enough to design requirements, or is the guide and lead screw does not match, thus wasting a lot of unnecessary costs.

Of course, to the design of the journey, in the process of another trick is to share with you, that is, when you choose to be a guide and guide suppliers to consult their guide specifications are according to what size to intercept, especially some foreign suppliers, such as Japan THK, Germany rexroth, etc., of course, China's Taiwan province and so on of silver (remember that Taiwan is a part of our country), their guide are all specifications, as far as possible to choose according to their specifications, the purchase price will be cheaper, we, for example, for example, we are going to a 1500 mm of guide rail, If Japan THK guide specifications is 1600 mm, it in order to meet our requirements, they need to rework, send us the length of the truncated to 100 mm, cut the processing fee is need for this time of the charge, and if we directly use the length of 1600 mm, it will be cheaper, because it is their standard specifications, in the process to eliminate the secondary processing costs, although it is a little long, but instead more advantage on price, so in the design process, the need for these skills to skilled application.

3. shield shell effective stroke, to get this thing alone, because many small factory, the designers in the design of shield shell is not well corresponding to their actual schedule for design, give the reserved amount to die too, so a lot of time was supposed to lead screw and guide rail journey are support further enlarged, but the mount guard, only to find out, was turned on to pull the shield shell rotten, or feed motor overload alarming, etc., so when we set of machine tool, also want to have a look at the actual operation of the distance, lest appear this kind of rigid collision, Thus damage the geometric precision of the machine tool.

And also need to pay attention to a very small features, and the drag chain, most of the time in all kinds of machine tool feeding schedule for movement are relatively long distances, so for all kinds of power cord and switch, we can protect it with a protective drag chain, and the protection of the drag chain extension distance is also needed and machine tool supporting the schedule and also to a certain extent to absolute is greater than the machine, if you set the machine schedule, also needs to look at, protective drag chain whether enough distance to allow you to set the schedule and try to avoid hard pull, to cause the damage of the drag chain, this place doesn't damage the machine, Because the tow chain is plastic, the broken one is usually the tow chain.

So, to sum up, in the setting of the machine tool all the trip, to comprehensive consideration of various factors, rather than just watching some indicators are arbitrary conclusion that is industrial machine tool machine tool equipment, it is to belong to more sophisticated processing equipment, especially not is hard to collide, the schedule Settings are appropriate, is the first premise of avoid machine rigid collision, so must be in line with the careful and strict attitude to do the work.

Page location :

Page location :